Lı-ıon batterıes

Li-ion Batteries

Li-ion batteries are under constant challenge to improve performance and reduce cost by material and process developments. Since its introduction, the cost/performance has steadily improved by 8 % per year over a period of 20 years, a process that still continues. Currently, challenges in Li-ion batteries are i) cycle life at deep discharge, ii) safety, iii) the high cost. Efforts at ENDAM within this framework concentrates on both cathode and anode materials

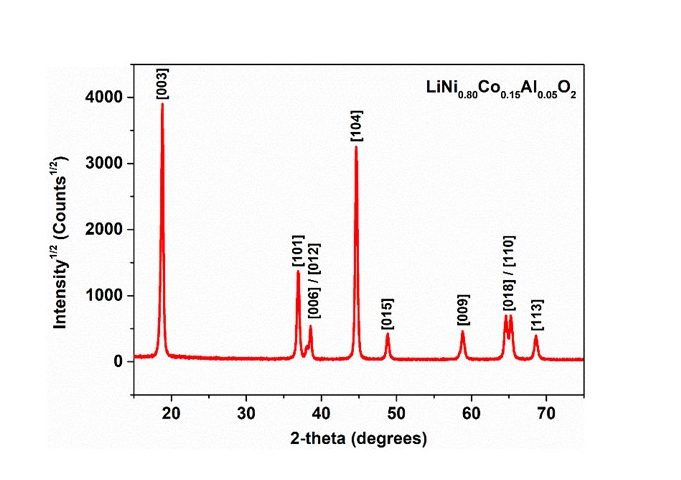

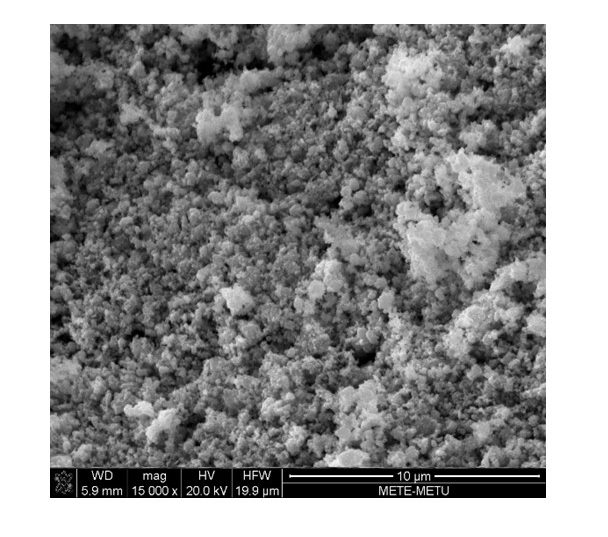

XRD Pattern of NCA compound SEM micrograph of NCA compound synthesized

through sonochemical processing

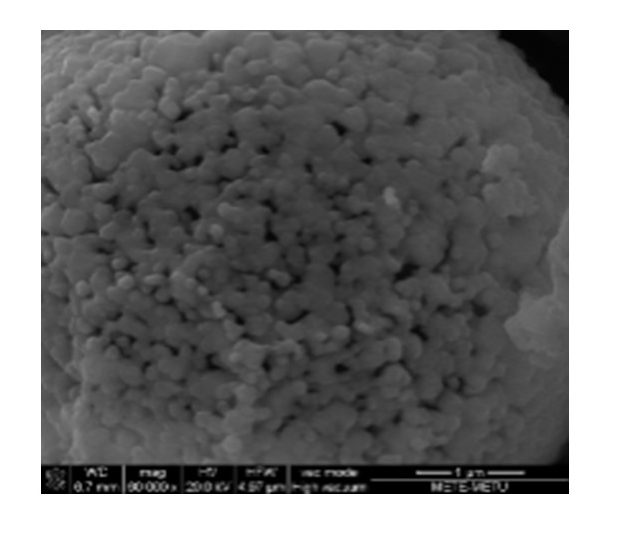

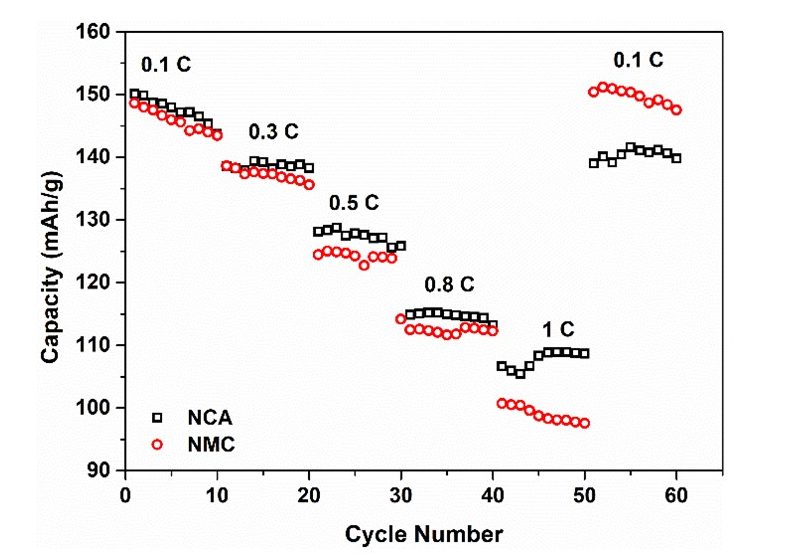

Cathode Materials: Activities at ENDAM on cathode materials have centered on layered transition metal oxide as they have enhanced kinetics. Thermal and structural stability have been addressed via alloying both in NMC and NCA compounds. Optimized chemistry yielded an improved capacity retention. NMC and NCA preserved their 65 % and 72 % of capacity during cycling at ( 1C). Applying recovery cycling at a slow rate improved this values up to 99 % (NMC). The value in the case of NCA was 93 % .

.SEM Micrograph of NMC compounds Capacity retention in NMC and NCA cathodes

………………….. …………………………………………….at different discharge rate

Anode Materials Activities at ENDAM on anode materials covers graphite, silicon as well as tin. Currently work is in progress to develop graphitic materials with controlled interlayer disctance as as to enhance high rate dischargeability. In the case of silicon and tin, the aim is to develop carbon encapsulated active materials so as to improve the conductivity and the integrity of the anode material.